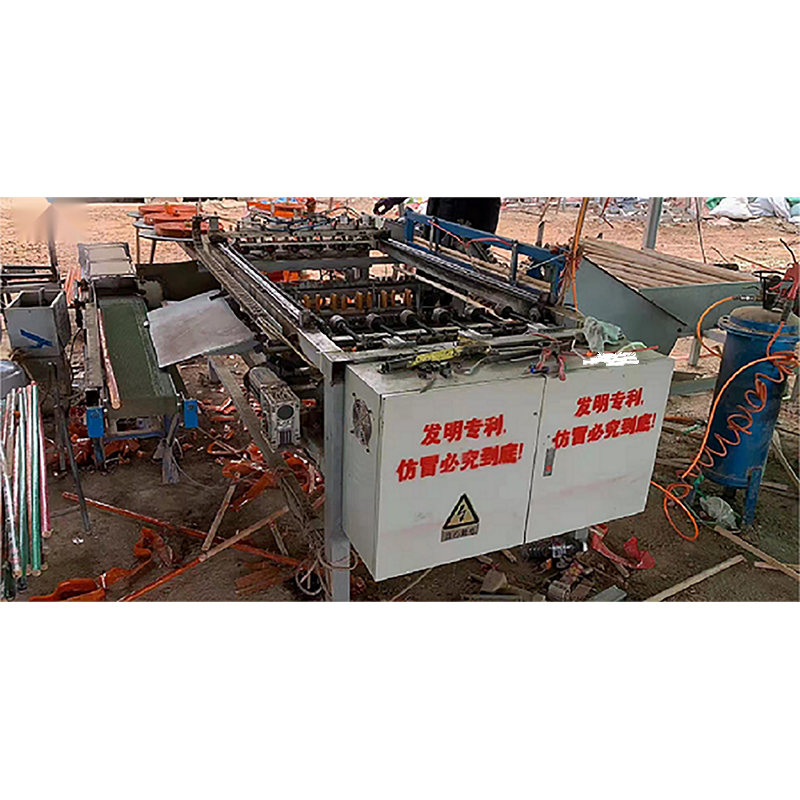

High Capacity Broom handle coating machine

Details

The broom handle PVC coating machine mainly used for producing the wooden

broom with PVC coated,and equipped with automatic discharging conveyor.Our machine can process

6pcs broom handles at one time.The advanced U shape heating technology assures that the brooms are heated evenly.

Our machine is energy-efficient and environmental-friendly,with only 8 kw

power consumption.At the meantime,high capacity is one of the outstanding features of our machine,for

that it can produce 50-60 brooms in just one minute.

Servo motor is also equipped,after brooms are coated,they will be taken to the next procedure.

Finally,the coated brooms need to be heated so that the shrink film can fit tightly with them.

Finished products can be packed in woven bags after nailing the plastic caps.

when we deliver,we will send you the manual,explain you 100% clearly for how to set up,at the same

time we will send you the video to show how.Totally the machines are composed by three parts,we will mark numbers on the parts of the machine,when you receive can connect them one by one in order.when every part connected,then can adjust like below:Plug in,this is the electric box switch,down is to power off, press up is turn on power,after all installation looks like this,Turn on the emergency stop button,Rotate

in the direction of the arrow,push the sticks,press green button to begin the work,press the emergency button there are several operations can work separately,the first operate is “clamping” the second operate is

“take off film(top output)” “advance” “return” “raise”,“position”, here is the “next page” “cut” pls pay

attention the cuts, film length adjustment

The above add how many numbers the bottom then deduct same numbers,

Adjustment is required when the collet is loose,twist the nuts both side to adjust

Until it is not easy to pull out the film like the video,clamping head film need to change when wear out.

bend it then install,when change the film need to raise up,Use one stick as to mark the position,loose the

nuts behind the film,take out the old film and insert the new one,tight the nuts,make the stick just in the

middle of the hole,then is ready to produce.

Technical parameter

| Model | CRS-BH |

| U Shape heating tube | 5KW |

| First feeding motor | 1.5KW |

| Second feeding motor | 0.75KW |

| Servo motor | 0.12KW |

| Discharge conveyor | 0.15KW |

| Heating tube length | 50mm |

| Capacity | 50-60 PCS per min |

| Air compressor | 0.4 MPa |

| Total power | 8KW |

| Machine size | 4m x 1.5m x 1m |

| Machine weight | 1000kg |